The joints of the body are a wonder of mechanical engineering. A simple squat, for example, places four times the body weight on a healthy knee joint without causing the squatter the slightest pain.

Trent Guess has a deep appreciation for body mechanics. While studying for his doctorate in mechanical engineering at the University of Kansas, he became fascinated with the mechanics of human joints, especially the knee. Today, the trained engineer who once worked as a designer of computer hard drives leads the Mizzou Motion Analysis Center, which combines the tools of engineering with the clinical expertise of physical therapy and orthopedics.

“Some of the control techniques I learned designing hard drives, we are using here,” Guess said recently while conducting research in the motion lab in the basement of Clark Hall. “Mechanical engineering can actually help with things I thought were outside my realm.”

That a mechanical engineer is part of human joint research is a testament to the interdisciplinary culture at MU. Engineering professors and students work alongside faculty and students in the School of Health Professions and other disciplines to solve problems.

“There is no way any one discipline could tackle problems like this,” said Guess, the HealthSouth associate professor of physical therapy in the MU School of Health Professions and of orthopaedic surgery in the MU School of Medicine. “It takes biologists, clinicians, engineers and others to tackle the incredibly complex joints of the human body.”

Guess recently co-authored a paper on the menisci, which are rubber-like pads of cartilage tissue on the knee between the thigh and shin bones. In March, the paper appeared in the online Journal of Biomechanics under the title “Predicted loading on the menisci during gait: The effect of horn laxity.” The paper’s other co-authors were MU’s Swithin Razu and Hamidreza Jahandar, and Antonis Stylianou of the University of Missouri, Kansas City.

Menisci absorb the tremendous force of the upper leg on the lower leg, and improve knee movement and stability. But over time, menisci lose flexibility and can easily be injured. They are also prone to osteoarthritis.

They are also prone to osteoarthritis.

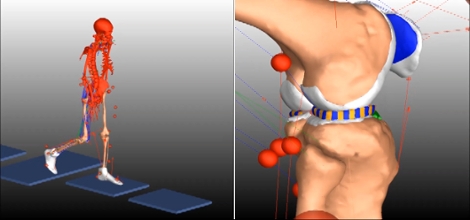

In the motion lab, which opened in Clark Hall in summer 2014, technology can track the force placed on human joints and on cartilage like the menisci. Researchers place quarter-size motion markers on the bodies of patients. Video cameras track the markers, which a computer transforms into a moving schematic of active joints. On the test-area floor are tiles wired to measure force when a participant steps or leaps on them. Computational models estimate the force on knee ligaments and cartilage, including the menisci.

Early signs of osteoarthritis include aberrant joint force that the developed models can track, offering the potential to catch the disease early and begin medical treatment.

A model that predicts loads on human tissue has many applications for knee treatment. “There are models of the knee and there are models of muscle movement simulations,” Guess said. “We have a model that combines the two.”

“It is a new way of looking at the knee joint,” Guess continued. “I can build a model of the meniscus, but if it is not based on an actual person’s condition, we receive limited information.”

Though Guess enjoyed his computer-engineering work, applying mechanical engineering to help someone walk comfortably has its rewards, too.

“What I am doing now is much more satisfying,” Guess said.